NewPro permaResist polymer 600 UV-curing scratch-resistant coating for plastic surfaces.

Product Description:

A highly transparent, scrub-resistant one-component coating for use on most plastic surfaces with excellent adhesion properties without the need for primers. Energy-efficient UV curing means the product can be applied easily on slabs, foils and three-dimensional parts. Its high solvent-, UV- and hydrolytic resistance makes Nano-SRC 600 suitable for a wide range of industrial applications (e.g. displays, visors etc.).

Main areas of use: PC, PMMA, ABS, PVC, PEEK, PET.

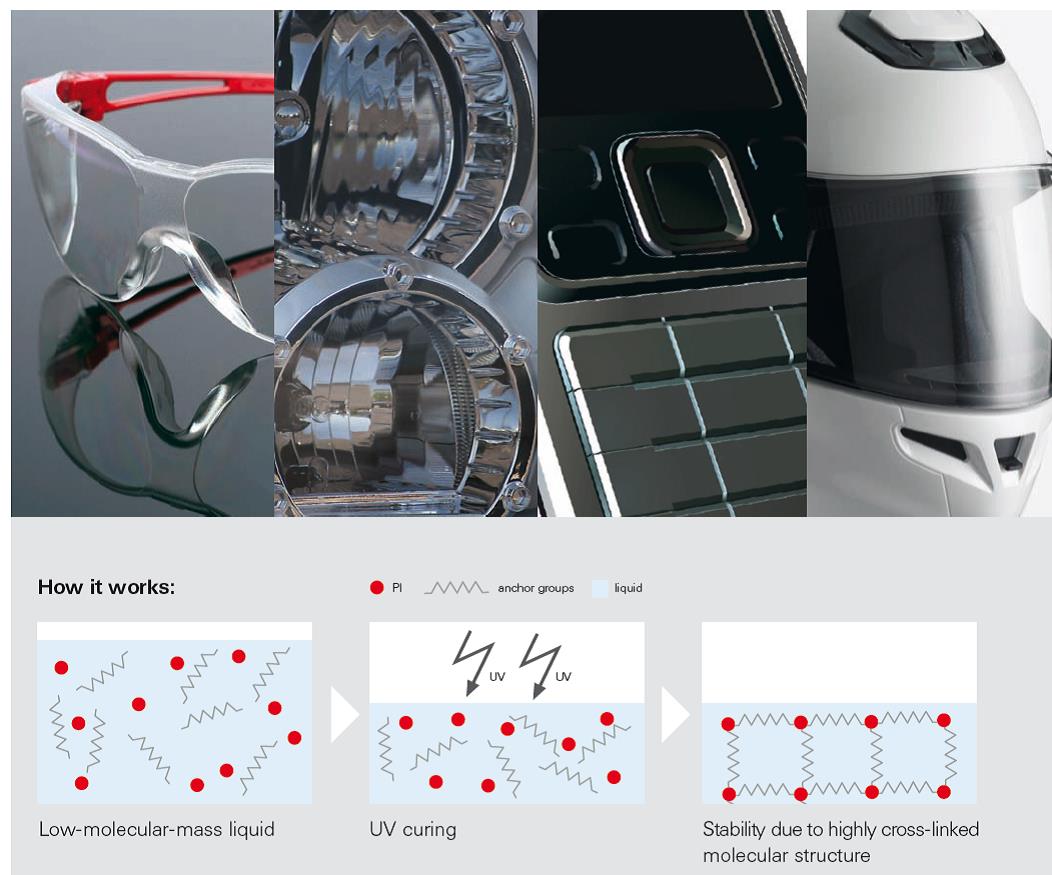

Based on: Nano-modified acrylate matrix, solvent-based.

Colour: colourless, transparent

Available quantities: See current delivery programme.

Storage/product life:

Store product away from direct sunlight. Unopened, in original container and at temperatures of 5°C to 35°C (41°F to 95°F), storage is possible for at least 6 months. Protect from moisture, frost or temperatures above 35°C. Check for signs of deterioration if the recommended storage period has been exceeded. Seal tightly after opening. Storage areas must be well ventilated.

Preparation:

The product can be applied directly from the container. Please refer to separate instructions.

Application: Spraying, dipping or flooding. See separate instructions.

Processing temperature: At room temperature.

Coverage:

Varies according to type of application. At approx. 5 µm thickness of cured coating, coverage is 20g per sq metre.

Safety advice:

Please refer to instructions and health & safety advice on the packaging and ensure compliance with relevant industry Health & Safety regulations. For further information see material safety data sheet.

Disposal: Dispose as industrial waste according to local and regional regulations.

Technical data:

Gloss(DIN 67530): 20°: 86 / 60°: 93

Transmission (PMMA): PMMA uncoated: 92,3% PMMA coated: 91,7%

Pencil hardness: on PMMA 7 H on PC 3 H

Hardness Test (Erichsen test rod 318): on PMMA 15 N / on PC 5 N

Taber Abraser Test (CS10 F wheel, 500 rotations) ASTM D 1003:

haze <10% auf PC, PMMA no measurable shrinkage

Solvent-resistance (24 hrs at RT): 2-Propanol, Ethanol, Aceton, n-Hexan, Toloul, Xylol

Chemical resistance: ph 2 bis ph 14

This technical data sheet has been compiled on the basis of our latest technical knowledge and experience. Considering the wide variety of different surface materials and conditions, it remains the user's responsibility to determine suitability of the intended application for the specific purpose and to use their judgement and technical expertise in assessing the surface conditions. Since conditions of use are not under the manufacturer's control, the content of this technical data sheet cannot be taken as acceptance of any liability. Terms & conditions apply. This data sheet will be superseded by any later versions released.